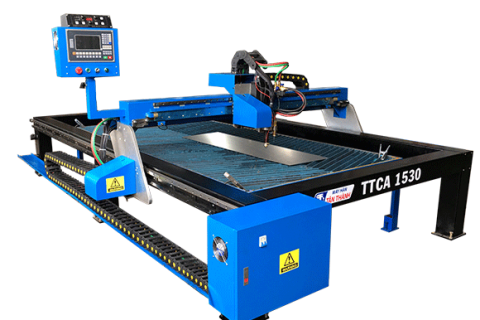

Mô tả chi tiết

Arc welding machine is a device widely used in the field of steel structure construction such as: pre-engineered steel buildings, factories... as well as in industrial manufacturing.

The TTT500 arc welding machine uses a 3-Phase - 380v power source, has a strong output capacity of 32kva allowing the machine to operate at maximum capacity, has a frequency of 50/60Hz, output current of 500A, the machine uses wire diameter welding 1.0~1.2mm, suitable for welding objects with thickness from 4.0~12mm, welding speed is 15-50(M/h). The machine is designed to ensure sufficient capacity, stable working efficiency, high durability, and the ability to perform work with high capacity. The machine has a heat dissipation system that ensures the machine always operates at maximum capacity, and has an automatic overheating alarm system to help all welders feel secure when using it at work without worrying about interruptions or delays compared to schedule. construction. Arc welding machines are used automatically, so they are less dependent on labor, cost-effective, high productivity, compact, flexible and can be used for different types of trusses. Protected with solder so the weld does not have air porosity, the weld penetrates deeply, the weld is even and smooth. Automatic arc welding machine under the flux layer is a welding method in which all stages of the process are carried out automatically by the welding machine, including: causing an arc, moving the welding electrode down to the weld puddle to maintain the arc. Stable combustion, moving the welding point along the weld, supplying welding flux. This is one of the technologies that has many advantages such as: no smoke generated, closed arc; Does not require high welder skills; High welding productivity, good and stable weld quality The welding machine is compactly designed, with an extremely sturdy outer frame, durable coating, does not take up too much space in the factory or warehouse, and is designed with 4 trolley wheels attached to a sturdy machine body, for ease of use. Easy to move around at work. Because the welding equipment is designed to be simple and flexible, arc welding is one of the most popular welding methods in the world today and has wide applications in life and production, including: like: Suitable for welding objects of relatively small and medium thickness with many different positions in space. Occupies many advantages over other welding methods in the repair and restoration industry. Arc welding is widely used in steel structure construction and industrial manufacturing. Often used to weld carbon steel, high and low alloy steels, some stainless steels, ductile iron and gray cast iron (rarely used to weld non-ferrous metals such as nickel, copper, aluminum and their alloys). . Advantage: Thyristor control technology (SCR). High working efficiency. Easy to operate and safe to use. Welding turtles are light in weight and convenient for users

VIDEO:

Tan Thanh welding machine, durable, high durability: Tan Thanh welding machine is manufactured from high-quality electronic components, imported from Sanrex, Toshiba, helping the welding machine have durable quality, confirmed in the market. welding machines for the past 35 years. Along with warranty and regular maintenance, customers can feel secure when using and choosing Tan Thanh welding machines.

Tan Thanh welding machine always gives customers: "The best quality - Design - Price - Service" - HELPING YOU PEACE OF MIND WITH THE PROGRESS OF THE PROJECT.

The product has a 12-month nationwide warranty.

| Điện thế vào (V) | 3Pha - 380V |

| Tần số (Hz) | 50/60 |

| Công suất (KVA) | 32 |

| Điện thế ra không tải ( V) | 65 |

| Cường độ dòng ra (A) | 500 |

| Chu kỳ công tác (%) | 60 |

| Trọng lượng máy (KG) | 176 |

| Trọng lượng rùa (KG) | 19 |

| Đường kính dây hàn (mm) | 1.0~1.2 |

| Kích thước (cm) | 76*45*81 |

| Tốc độ hàn ( M/h) | 15-50 |

Tan Thanh Welding Machine is a welding machine brand familiar to Vietnamese welders and mechanics with the Tan Thanh Stick, TIG, MIG, and Plasma Welding Machine product lines famous for their durability, ease of use, and beautiful welds.

- Rùa hàn tự động + 15m cáp nối rùa

- Dây mass 2m + 1 kẹp mass 600A (100% đồng)

- Bánh xe dẫn dây HQC 1.0-1.2

- Cầu chì (3A + 5A + 10A)x4, 01 lục giác

- Béc hồ quang chìm (1.0+1.2)x5

- Dây nguồn 4m (100% đồng)